This is a case study about working as a Purchasing Manager at a small-sized company. But the principles apply to companies large and small.

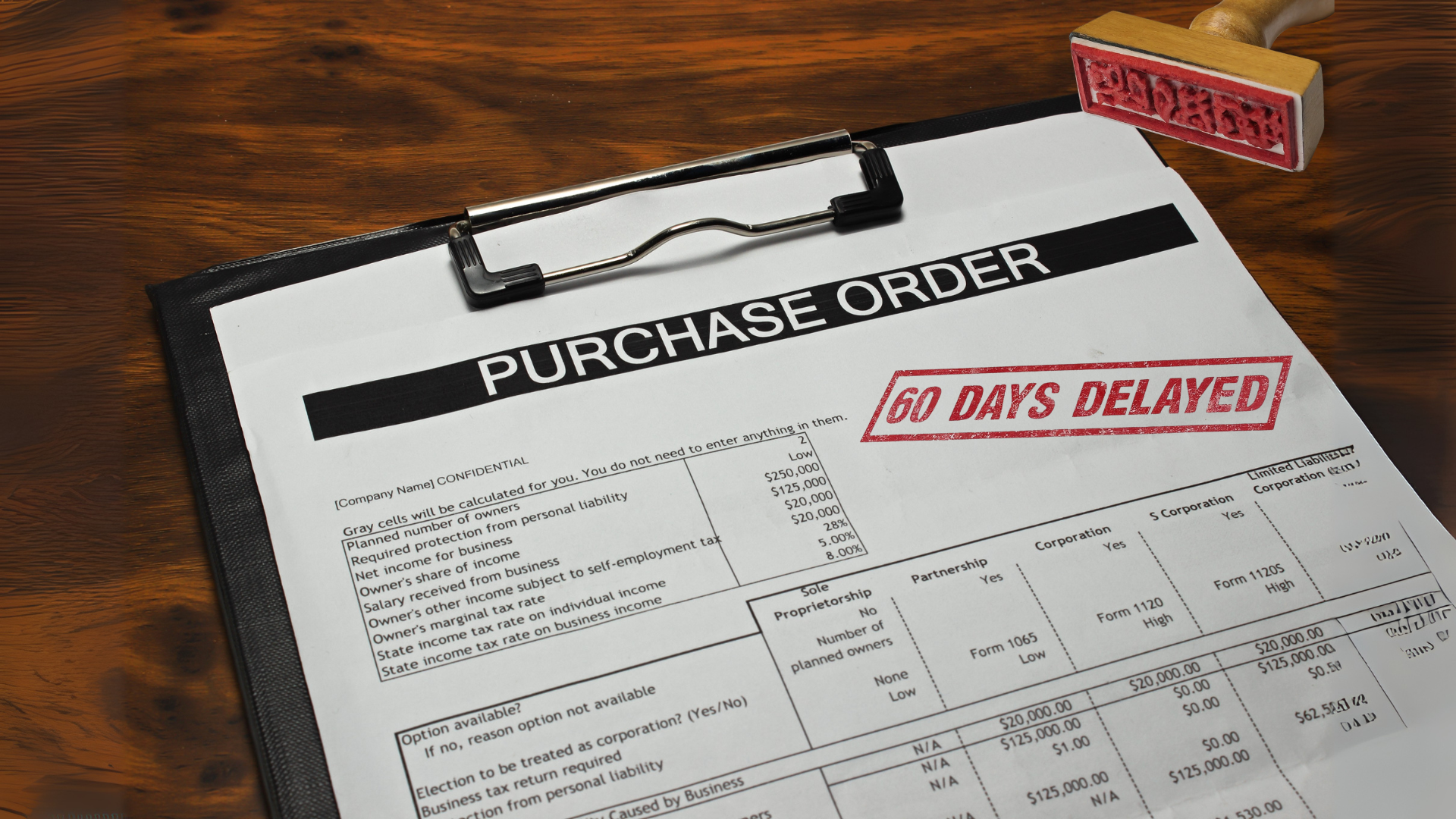

One of the core goals for a purchasing manager is to reduce costs, right? But as purchasing manager, I also need to have product, and support materials/tools available in our hands. Something that is lowest price isn’t worth much if it is just an open purchase order on a vendor’s books. The “normal” tactics are to hammer your suppliers into submission for the deepest discounts. Play hardball.

Use the “Best and Final Offer” (BAFO) tactic that some procurement folks treat like gospel.

But I didn’t.

Because I knew the field teams counted on parts being available. Not “cheap” parts—available ones. And I had already seen the cost of short-term thinking.

What Is BAFO Anyway?

BAFO is a common negotiation strategy where you ask suppliers to submit their absolute best price or offer, with the implication that there won’t be further rounds. On paper, it sounds efficient. In practice, it often backfires.

It’s a tactic born out of zero-sum thinking: “If they win, I lose.”

Think of it as a math equation. If you treat non-delivery as zero, you can quickly understand how important non-price factors weigh in on reality.

But when you operate like that, you’re not building a supply chain. You’re building a house of cards.

Why I Took a Different Path

Instead of trying to squeeze every penny from my suppliers, I did something radical: I treated them like partners. We had honest conversations about lead times, capacity, and costs. I shared our field needs so they understood why delays were unacceptable.

And guess what? We got better service. Faster turnarounds. Real solutions during shortages. Because I wasn’t just another buyer in their inbox asking for a price cut. I was someone they wanted to help.

Lean Thinking Got Twisted

There’s a popular misunderstanding of Lean: that it’s all about cutting costs. But true Lean—the kind born in post-war Japan—was about reliability, trust, and long-term value. It came from a place of scarcity, not abundance. Every part had to count.

We’ve warped that mindset into endless optimization, over-Lean operations, and brittle systems.

BAFO fits neatly into this misinterpretation. It’s not Lean. It’s just lazy.

The Human Cost

Here’s the irony: while I was being quietly reprimanded for not always choosing the lowest-cost vendor, I was preventing outages that would have cost the company much more. The execs never saw that. They just saw numbers.

But your field team notices. Your customers notice. Eventually, even your CFO notices when your cost-cutting leads to chaos.

A Better Way

If you’re in procurement, operations, or executive leadership, consider this:

- Transparency beats tactics. Tell suppliers what you really need and why.

- Resilience matters more than rock-bottom cost.

- Long-term relationships protect you when things go sideways.

Want a real competitive edge? Ditch the BAFO and build something stronger.

This post is part of the Unlean Thinking Newsletter series, also featured on Medium and Linkedin. Because not everything efficient is effective—and not everything cheap is smart.